Vermeer Corporation

Vermeer Corporation uses Dassault Systèmes’ 3DEXPERIENCE platform on the cloud to streamline operations, protect data, and enhance communication.

Industrial Equipment Powerhouse Adopts New Ways of Working

The instructions that Vermeer Corporation Founder Gary Vermeer gave his employees more than 50 years ago were, “Find a need. Fill that need. And simply build the best.” Founded 76 years ago in Iowa, Vermeer Corporation evolved from a friendly conversation with a neighbor who expressed a desire to quit the industry because of the grueling nature of the farming business. Gary Vermeer knew there must be a better way.

Today, the second and third generations of the Vermeer family have built a global powerhouse that’s now recognized around the world. With an impressive 245 products spanning agricultural and industrial equipment across industry sectors, its customer base is diverse but shares one common trait: The desire to do hard work.

“We think of ourselves as a premium brand and one of the things that sets us apart is the customer service we deliver,” said Harold Sullivan, director of Product Lifecyle Management at Vermeer Corporation. “We provide excellent customer service and equipment that does things that other people and other equipment don’t do. We look for niche markets and niche needs that we can fill specifically.”

Managing Growth Along with Increased Challenges

As the company continues to grow, Vermeer faces the challenge of honoring the traditional engineering methods its employees have relied on for years while finding new ways to evolve its tools and processes.

“One of the challenges that we face, and I would expect all companies in the industrial equipment marketplace would struggle with, is optimizing our processes,” Sullivan said. “We have an excellent engineering team that does wonderful work, but they’ve been doing it the same way for a long time and they’re used to certain methods.”

Another challenge is increasing government regulation in the industrial and agricultural industry. Since 2017, the United States government has issued 56 new industrial regulations, which equals a new regulation every two months. With these mandated regulations comes a responsibility for Vermeer to be flexible and adjust its business processes accordingly.

“It seems like there is a new regulation in the industry every day and it’s hard to keep track and keep up with them all,” Sullivan said.

Dassault Systèmes is who we have selected to help us lay the foundation for a new unified process and system. We’re really happy, humbled and excited about the partnership that we’ve formed with them.

In the same span of time, Vermeer doubled its revenue, employee count and units shipped while increasing its physical footprint. With all these internal and external changes and advancements, Vermeer knew its business operations needed to evolve.

Individual teams within the company found new ways to manage their projects, but with no clear roadmap or solution to guide them, Vermeer ended up with 20+ storage locations for data, 53+ tools for project management and 25+ different sub-processes.

“What we’re trying to do now is create a unified organization where instead of having 245 different processes to match the 245 different products we have, we act as a single unified company with unified tools, systems and processes,” Sullivan said.

How is Vermeer finding this balance? By continuing its partnership with Dassault Systèmes. As long-time SOLIDWORKS users, Vermeer is eager to find new ways to use Dassault Systèmes’ solutions to unify its current operations. “Dassault Systèmes is who we have selected to help us lay the foundation for a new unified process and system,” Sullivan said. “We’re really happy, humbled and excited about the partnership that we’ve formed with them.”

Vermeer selected the 3DEXPERIENCE® platform on the cloud to help solve its current challenges while addressing the company’s new goals of improving efficiency and reliability, reducing overhead, working from a single source of truth and designing and building anywhere.

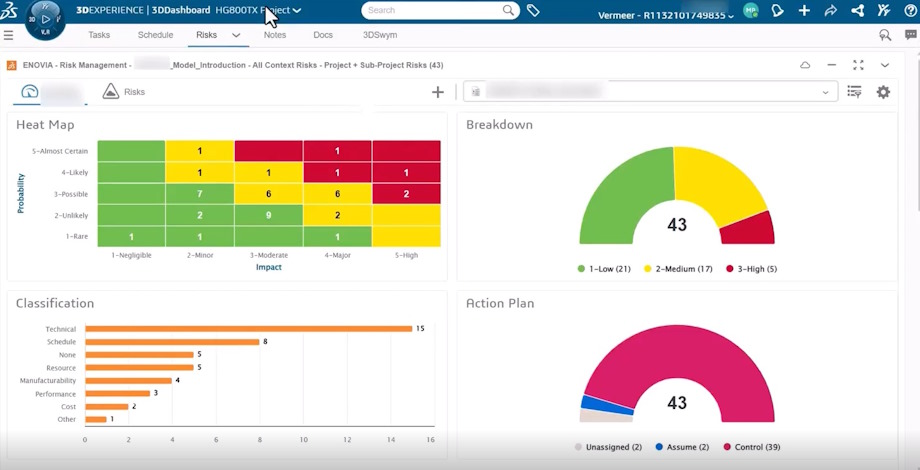

Using ENOVIA for project, product and data management, Vermeer’s engineers and project managers work more efficiently with real-time access to up-to-date design files and other key data.

“Cloud-Or-Else” Mentality Leads Strategic Direction

Deciding to “go cloud” was a very difficult decision for the company. “Traditionally, the nature and culture of Midwest farmers are hesitant to go digital,” Sullivan said. “We like to touch and feel everything that is around us and everything that we work with, including our data.”

However, when a real-life disaster hit Vermeer in the summer of 2018, management was forced to take a hard look at how they protected their products, data and employees. During the middle of a workday, a tornado hit Vermeer and destroyed two factories, representing 40% of its manufacturing capacity. The company was lucky enough to receive a generous amount of support from its business community through offers of facilities and resources, but every paper-based document and drawing in its facilities was blown away by the tornado.

It was a wake-up call that a “what-if” disaster scenario could become a reality. Vermeer quickly recognized data as an asset that needed to be protected. In order to secure its future and protect its assets, a paper-based strategy was no longer a choice.

Management also saw other benefits of moving to the cloud-based platform that drove the change, but they faced some hesitancy from its staff. “We had to show our engineers, and those in the product development circle, its value, and showcase the positive changes that can occur when you incorporate digital processes into your day-to-day workflow,” Sullivan said. “We showed them that it would not only improve their communication but also their own ability to do the tasks that are required of them every day. Ultimately, it’s about being as efficient as possible.”

When a real-life disaster hit Vermeer in the summer of 2018, management was forced to take a hard look at how they protected their products, data and employees. Vermeer quickly recognized data as an asset that needed to be protected – and thus moved to the cloud-based 3DEXPERIENCE platform.

Transforming Day-to-Day Operations with the 3DEXPERIENCE Platform

Prior to using Dassault Systèmes solutions, Vermeer designed every part of its large assemblies from initial 2D assembly drawings to complete designs, including electrical schematics and simulation for stress testing. Now with the 3DEXPERIENCE platform, Vermeer is actively moving forward with plans to create and explore virtual representations of its products, workflow and operations. Additionally, by connecting various file-based, on-premise systems into one single, cloud-based solution, Vermeer is that much closer to the company’s goal of streamlining common processes and standards, thus increasing visibility and communication.

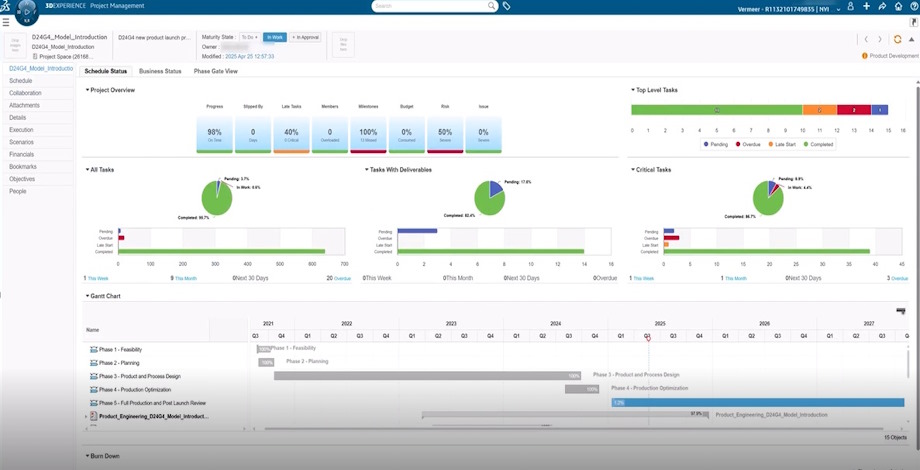

“One of the things we have already identified and seen value in is visibility,” Sullivan said. “People now know exactly what is going on and what stage each project is in. Everyone can see in which areas we are ahead and which areas we are falling behind on, and it allows us to manage teams in a more unified way.”

Using ENOVIA for project, product and data management, Vermeer’s engineers and project managers are transforming the product development process. Because the company’s employees all have real-time access to up-to-date design files and other key data, working practices are more efficient and collaboration is much improved.

Using ENOVIA to catalog and manage parts on the platform rather than sorting through thousands of rows on spreadsheets, parts management is less time-consuming and prone to error. A full view of its data allows Vermeer to make informed decisions and manage projects with precision to deliver quality products on time and in scope. In addition, since existing components can easily be reused in new designs, the entire design process is now much more efficient.

With computer-aided design (CAD) capabilities from SOLIDWORKS, product designers gain greater ownership over new machine designs with simple revision control and the ability to make updates from anywhere in the world.

With its efforts to unify its tools, processes and systems, Vermeer also sees the future benefit to scale at speed. “The cloud has challenged us to be more disciplined since you’re looking at configuration and unification rather than customization,” Sullivan said. “This is driving us toward that unified process and the ability to scale and grow at whatever speed we need.”

And with the cloud’s instant updates, projects aren’t slowed down when upgrading the system. “The support we get from the cloud is very reliable,” Sullivan said. “We are always at the latest and the greatest [release] whether it be a bug fix or a new functionality. We get these updates with very little impact or work on our part.”

One of the things we have already identified and seen value in is visibility. People now know exactly what is going on and what stage each project is in [...] and it allows us to manage teams in a more unified way.

Customer-focused Goals for the Future

As Vermeer continues its digital transformation, it’s now focused on how Dassault Systèmes solutions will support its growth and provide technological benefits to its customers.

“We’ve been working hard with Dassault Systèmes to find exactly what we will need for a business of our size and complexity in order to continue growing,” Sullivan said. “So far, the partnership has been fantastic and we have an excellent working relationship not only with the R&D teams but the company at large.”

A future goal of the company is to continue strengthening customer relationships by providing greater insights into their machines. “We are a very customer-centric organization and we want to be able to provide our customers with important data about their machines,” Sullivan said. “We want to get to a point where our customers have full visibility into the data of how their machine is designed, built and maintained and provide them with proactive information that will help the uptime of their machines. They don’t get paid if their machine doesn’t work, so we want to minimize that happening. Our goal is to provide a full downstream information chain to the customer.”

As Vermeer, whose humble beginnings and straightforward mission of “find a need and fill that need," looks to the future, the team is confident they’ll be supported by their partnership with Dassault Systèmes. By using new technology and innovation that both honors the Midwestern mindset and pushes it to new heights, the company is well on its way to “simply build the best.”

Focus on Vermeer

Vermeer Corporation is a leading manufacturer of industrial and agricultural equipment that provides machines to people all over the world for underground construction, infrastructure, surface mining, tree care, environmental and agriculture. They are a family-owned and -operated company headquartered in Pella, Iowa, U.S., with regional offices in various locations around the United States as well as the Netherlands, Brazil and China.

For more information: https://vermeer.com/na