BOM Management

Empower manufacturers to drive collaboration, increase efficiency and unlock digital transformation across the product lifecycle

What is BOM Management?

A Bill of Materials (BOM) serves as the cornerstone of product development and manufacturing, providing a detailed list of all components, materials and instructions required to create a product. Effective BOM management is critical for ensuring accuracy, efficiency, and collaboration across teams, making it indispensable for industries such as aerospace, high-tech, automotive and consumer packaged goods. Without proper BOM management, businesses face risks like production delays, cost overruns and miscommunication, which hinders overall operational success.

Optimizing BOM Management: The Key to Innovation and Efficiency

A well-structured BOM includes key details such as part names, descriptions, quantities, unit measurements, part numbers, cost information, sourcing details, assembly instructions, engineering notes and revisions to ensure accuracy and completeness. Acting as a single source of truth, it facilitates seamless collaboration between engineering, procurement and manufacturing teams.

Modern BOM management systems integrate with tools like enterprise resource planning (ERP) and product lifecycle management (PLM) systems, enabling data synchronization, traceability and compliance with industry standards. This integration minimizes errors, streamlines production workflows and helps businesses adapt to changes like new designs, supplier updates or market demands, ultimately driving innovation and operational efficiency.

Streamlining BOM Management with the 3DEXPERIENCE Platform

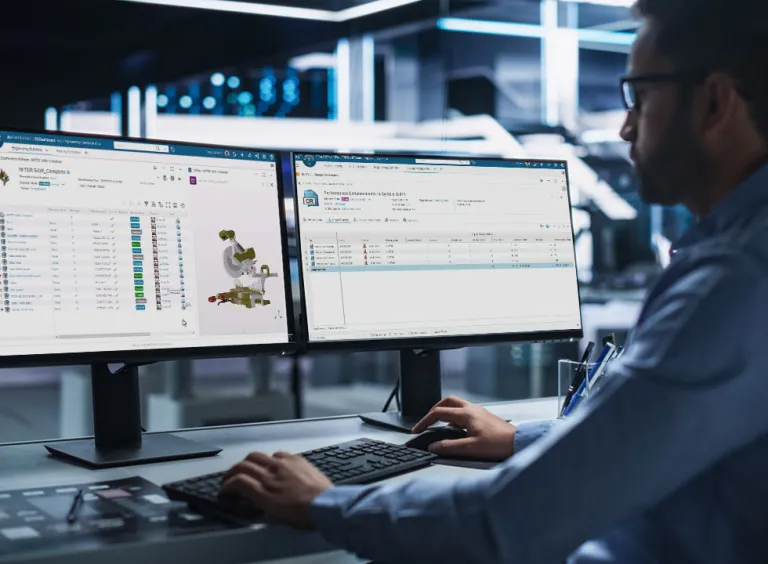

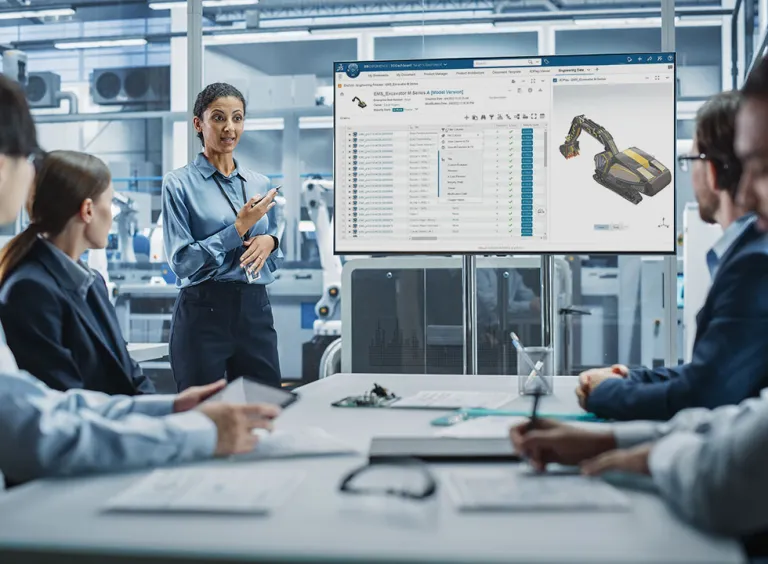

The 3DEXPERIENCE platform enhances BOM management by providing a unified environment where teams can collaborate on the product definition in real-time. It connects design, engineering, manufacturing and other departments, ensuring that everyone has access to the latest product information.

With 3DEXPERIENCE, organizations streamline processes, reduce errors and accelerate time-to-market while maintaining full control over their product lifecycle.

Core Pillars of BOM Management

Accuracy and Consistency

Ensure all components, materials, and data in the BOM are precise and up-to-date to avoid errors and miscommunication.

Collaboration Across Teams

Enable seamless communication between engineering, manufacturing, procurement, and service teams to align on product requirements.

Version Control and Traceability

Maintain a clear record of changes and revisions to track updates and ensure compliance with design and production standards.

Integration with Systems

Connect BOM management with tools like PLM, ERP, and CAD software for streamlined workflows and data sharing.

Sustainability and BOM Management

How BOM Management Supports Sustainable Product Lifecycle

Sustainability is an integral factor in modern product lifecycle management, and BOM management plays a pivotal role in achieving this objective. By incorporating sustainable practices into BOM processes, organizations can make informed decisions about material sourcing, production techniques, and end-of-life strategies. Furthermore, integrating sustainability into BOM management meets growing regulatory requirements and aligns with market expectations. This proactive approach ensures that businesses remain resilient and adaptable while contributing positively to global environmental goals.

What are the Different Types of BOMs?

Engineering BOM

An Engineering Bill of Materials (EBOM) is a comprehensive product recipe structured from the design perspective, originating from engineering software such as computer-aided design (CAD) or electronic design automation tools. It encompasses raw materials, components, parts, subassemblies, and interrelated data layers essential for product creation.

An EBOM focuses on parts as they exist in the design sense, typically listing items from an engineering standpoint. It serves as the foundation for transitioning a product from concept to production, ensuring design accuracy and alignment with technical specifications. Additionally, the EBOM facilitates collaboration between engineering and manufacturing teams, bridging the gap between design intent and production requirements.

Manufacturing BOM

The Manufacturing BOM (MBOM) is a comprehensive list that includes all materials, components, and subassemblies required for the production process. The MBOM is used by manufacturing and assembly teams, ensuring efficient production workflows. It accounts for manufacturing-specific details such as packaging materials, assembly sequences, and tools required for the production cycle.

The MBOM often incorporates data from multiple departments to reflect an accurate depiction of the entire manufacturing process, enabling seamless communication between engineering, procurement, and production teams. Effective management of the MBOM ensures that all necessary resources are available when and where they are needed, reducing downtime and errors during manufacturing.

Service BOM

A Service BOM (SBOM) is tailored for service operations, including the preparation of field instructions, spare parts management and connected support services. The SBOM is a critical tool for ensuring the longevity and reliability of products in the field. It helps service teams identify and source the correct parts for repairs or routine maintenance, reducing downtime and improving customer satisfaction.

By having a well-structured SBOM, companies can streamline aftermarket support, optimize inventory management for service parts, and ensure quick resolution of issues. Additionally, the SBOMs can include detailed instructions, diagrams, or annotations to aid technicians during the maintenance process, further enhancing the efficiency and accuracy of repairs.

Key Features of BOM Management

Transforming BOM Management on the 3DEXPERIENCE Platform with the Product Release Engineer Role

The ENOVIA “Product Release Engineer "role plays a pivotal role in streamlining and enriching BOM Management by providing a centralized, accurate and real-time engineering product definition accessible across multi-disciplinary teams. Whether it’s mechanical, electrical or systems engineering, the Product Release Engineer role ensures all stakeholders are working from the same source of truth—improving collaboration, reducing miscommunication and enabling faster design iterations.

By maximizing data reuse, simplifying product structures and establishing early product part numbers, Product Release Engineer helps reduce the time required to define the engineering baseline. It also strengthens governance by assigning responsibilities clearly and ensuring compliance with organizational standards from the start. Powered by the 3DEXPERIENCE platform, it offers a modern, web-based experience for reviewing, validating and sharing design and product information. This seamless flow of accurate data ensures that BOMs are both technically sound and aligned with procurement and manufacturing needs—ultimately accelerating product release and time-to-market.

How Companies Use ENOVIA PLM Solutions

Customer Stories

Soosan Cebotics

One of the biggest advantages of Dassault Systèmes’ solutions has been the transformation of bill of materials (BOM) preparation. By implementing a 150% BOM structure with ENOVIA, which encompasses the core product plus all potential configurations, Soosan can now automatically generate customer-specific BOMs.

We previously struggled with inconsistencies due to a lack of the right tools. Now, with BOM automation, we anticipate over a 50% improvement in accuracy. Since everything is already structured correctly, no additional processing is needed.

Want to Learn More?

Explore the content below to learn more about BOM Management.

FAQs on BOM Management

Also Discover

Learn What ENOVIA Can Do For You

Speak with an ENOVIA expert to learn how our solutions enable seamless collaboration and sustainable innovation at organizations of every size.

Get Started

Courses and classes are available for students, academia, professionals and companies. Find the right ENOVIA training for you.

Get Help

Find information on software & hardware certification, software downloads, user documentation, support contact and services offering.