Specialized Manufacturing Machinery

Smarter, faster, more connected, all-in-one equipment machines are transforming the entire production process. Here’s how to stay ahead.

Driving Innovation in Specialized Manufacturing Machinery

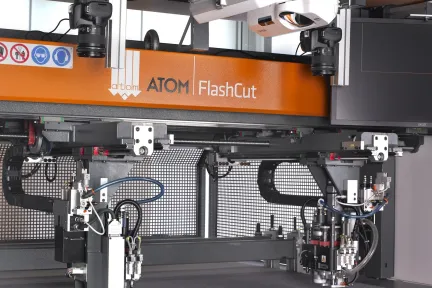

The manufacturing machinery industry is evolving rapidly. Specialized machinery is no longer defined solely by precision: It must also be flexible, intelligent and connected. Dassault Systèmes empowers machine and line builders to navigate this increasing complexity through digital transformation, smart adaptive equipment design and virtual twin experience — tailoring solutions that meet their specific needs.

Key Challenges in Specialized Manufacturing Machinery

What’s standing between you and your next innovation in specialized machinery? Customers want smarter, faster and more flexible machines — and they want them now. To stay competitive, manufacturers must overcome complex development cycles, accelerate machinery upgrades and mitigate rising operational costs.

- Accelerate Innovation

- Meet Demands for Mass Customization

- Integrate Systems and Services

- New Business Model

- Explore New Markets

High competition in the global market puts industrial manufacturers under pressure to bring innovative products to market faster than ever. Specialized manufacturing machinery companies face the dual challenge of accelerating development cycles and building more complex and connected equipment, which integrates mechanics, electronics and software and operates seamlessly within the wider production environment.

Success depends on their ability to implement a system of systems approach, which supports concurrent engineering across disciplines with precision and allows for effective collaboration with customers at every stage.

Manufacturers face growing demands for engineer-to-order and configure-to-order equipment without driving up costs or lead times. To meet these demands, specialized manufacturing machinery original equipment manufacturers (OEMs) and line builders must become more flexible and agile within manufacturing facilities by enabling adaptive equipment and reconfigurable systems powered by digital continuity. They must define customer requirements earlier in the development phase and embrace modular design for fast, affordable customization.

To increase efficiency and productivity gains, they’re also embracing virtual commissioning, which allows customers to verify designs virtually and test performance and interoperability ahead of installation — forming the essence of flexible production lines.

In today’s experience-centric economy, industrial manufacturers are evolving into systems integrators and service providers to foster closer customer relationships and tap into new revenue streams.

More specialized manufacturing machinery will be delivered as part of an added-value services package covering equipment continuity, process optimization, energy management and more. Virtual twin capabilities support this by providing the ability to simulate and virtually test product interconnectivity and behavior. Combined with IIoT, manufacturers can collect and analyze operational data for preventive maintenance and global asset monitoring.

The manufacturing machinery industry is undergoing a profound shift driven by changing customer expectations and rapid technological advancement. Today, end users increasingly prefer paying for experiences and outcomes rather than simply purchasing a new product.

This change is reshaping the business models of machinery manufacturers. OEMs are now expected to deliver equipment-as-a-service, where value is defined not by the machine alone but by the functions, services and outcomes it enables. As a result, OEMs must be agile and capable of rapidly tailoring solutions to meet specific customer needs during the inquiry-to-order phase.

These service-based business models are becoming increasingly vital. For many companies, services now represent 25% to 50% of total revenue and contribute between 80% and 120% of earnings before interest and taxes (EBIT), underscoring their strategic importance.

Companies that embrace digital transformation and adopt intelligent service-based models will be best positioned to lead in this new era.

Industry X developments around IIoT, cloud computing, artificial intelligence, smart sensors and machine learning put the onus on specialized manufacturing machinery companies to invest in the latest technologies and make ground with their own digital transformation journeys.

At the same time, they must adapt to fast-changing customer requirements and keep pace with global sustainability objectives. As the wider industry embraces outcome-based business models like equipment-as-a-service, OEMs must prepare to deliver connected services, continuously add new features and functionality and find innovative ways of tracking and optimizing machinery performance in the field — ultimately leading to field operations efficiency and data-driven after-sales services.

Sustainability in Manufacturing Machinery

Sustainability is no longer a secondary concern — it is becoming a defining factor in the competitiveness and resilience of machinery manufacturers. Today, specialized machine builders are increasingly embracing principles of circular innovation, energy efficiency and smart resource utilization to align with global environmental, social and governance (ESG) goals.

By integrating sustainability into every stage of the machinery lifecycle — from design and production to maintenance and end-of-life — OEMs can significantly reduce environmental impact while ensuring high levels of quality, reliability and performance. This commitment to sustainable production practices not only supports regulatory compliance but also enhances brand reputation and customer trust in increasingly eco-conscious markets.

One of the key enablers of sustainable transformation is digital continuity — the seamless integration of data and processes across the product lifecycle. By leveraging digital tools such as virtual twins, simulation and real-time data monitoring, manufacturers can:

- Optimize designs for energy efficiency and material reuse

- Simulate and evaluate environmental impacts before production

- Minimize waste and emissions during operations

- Monitor energy consumption across the factory floor

- Extend machine lifecycles through preventive maintenance and upgradeable modular systems

Ultimately, sustainable innovation in machinery design and manufacturing leads to a win-win scenario: It drives operational efficiency, reduces total cost of ownership and contributes to a more responsible industrial future. Manufacturers who lead in this area are not only future-proofing their business but also actively contributing to the global transition toward a low-carbon economy.

How to Transform Your Specialized Manufacturing Business?

Empower Innovation With Simulation and Virtual Twins

Simulate machine performance, behavior and system interactions before build.

Learn more about virtual simulation and robotics collaboration.

Achieve Real-Time Production Agility

Monitor operations and optimize production in real time with data-driven insights.

Discover more about field operations efficiency and after-sales services.

Deliver Tailored Systems With Integrated Digital Sales

Accelerate sales and engineering alignment with immersive 3D configuration.

Get the 3D selling experience.

Explore the Future of Manufacturing

Key Benefits of Specialized Manufacturing Machinery With Dassault Systèmes

Faster Time to Market

Leverage virtual testing and validation to optimize designs early, minimize rework and launch products faster with greater confidence.

Increased Efficiency and Resource Optimization

Maximize throughput, minimize material waste and enable data-driven decision-making through advanced automation and real-time insights.

Preventive Maintenance and Zero Downtime

Utilize virtual twin technology and machine learning to anticipate failures, reduce unplanned downtime and extend machinery lifespan.

Scalable and Flexible Production Systems

Quickly adapt to changing customer requirements, production volumes and product variations — without costly disruptions.

Reduced Total Cost of Ownership

From design to deployment, optimize asset performance, energy use and maintenance to reduce operational costs throughout the entire lifecycle.

Improved Collaboration Across Teams

Enable seamless collaboration between design, engineering, manufacturing and service teams through a unified digital platform — reducing silos and accelerating decision-making.

Faster and More Accurate Customization

Easily configure machines for customer-specific needs using modular design and rules-based engineering, shortening the sales-to-delivery cycle.

Regulatory Compliance and Traceability

Ensure compliance with industry standards and sustainability regulations through built-in traceability, documentation and audit-ready digital records.

Enhanced Customer Experience & Service Innovation

Deliver added value through digital services (e.g., remote diagnostics, equipment-as-a-service, training simulations) and ensure long-term customer satisfaction.

Data-Driven Continuous Improvement

Use real-world operational data to drive continuous product and process improvement, feeding insights back into R&D and manufacturing.

Smart, Connected and Adaptable Machinery

By integrating IoT and connectivity into machines, OEMs can monitor usage, analyze performance and offer value-added services that enhances profitability.

New Revenue Streams

Connected equipment allows for performance-based contracts, where customers only pay for uptime or output. This model provides clear value to the end-user while opening new revenue streams for OEMs.

Virtual Twin Technology and Manufacturing Machinery

In today’s fast-changing industrial environment, manufacturers of specialized machinery must respond to unprecedented demands for speed, flexibility, sustainability and customer-centric innovation. At the heart of this transformation lies our virtual twin technology, a cornerstone of Dassault Systèmes’ generative economy strategy — a bold vision where innovation is not only efficient and intelligent but also regenerative by design.

The virtual twin experience redefines how machines and production lines are conceived, tested, operated and continuously improved. OEMs can simulate and validate performance in a dynamic, real-world context before committing to any physical resources. This eliminates wasteful iterations, shortens time to market and ensures that every machine is built to meet specific operational goals and customer expectations.

But the real power lies in what happens after deployment. By integrating real-time data from IoT-connected machinery, the virtual twin becomes a living system — enabling predictive maintenance, adaptive performance tuning and on-the-fly reconfiguration to meet shifting demands. It’s not just about efficiency; it’s about resilience and responsiveness at scale.

This approach directly supports Dassault Systèmes’ generative economy vision, which aims to rethink value creation — moving from linear, resource-intensive models to circular, collaborative and regenerative systems. In the context of manufacturing machinery, this means designing equipment that not only performs better but learns, evolves and contributes to long-term environmental, economic and societal value.

With the virtual twin as a strategic enabler, OEMs can close the loop between engineering and operations, unlocking a continuous cycle of innovation grounded in real-world performance. They can reduce emissions and material waste, extend equipment lifecycles and offer new service-based business models like equipment-as-a-service — all while delivering greater customer outcomes.

Our Success Stories in Specialized Manufacturing Machinery

FAQ – Specialized Manufacturing Machinery

Explore Our Solutions for Specialized Manufacturing Machinery

Learn how our Industrial Equipment Industry Solution Experience can transform your business and enhance profitability.