Virtual Twin Experiences for Manufacturing Industries

Explore how virtual twin technology powered by AI revolutionizes product development, lifecycle management, supply chains and other key areas of manufacturing industries.

What is a Virtual Twin for Manufacturing Industries?

Manufacturing Industries drive innovation and enhance people’s lives by developing innovative and sustainable products through circular practices, resilient systems and advanced technologies.

They help shape a stronger future by transforming raw materials into finished or semi-finished goods through streamlined industrial processes, to produce vehicles, electronics, industrial equipment, textiles and more.

At the heart of this transformation lies the virtual twin: a data-driven and executable digital model representing real-world components and operations. Grounded in scientific laws, virtual twins integrate real-time data to simulate behavior with precision, enabling efficient process control, product monitoring, and continuous improvement from design to end of life.

At Dassault Systèmes, we believe that virtual twins are the cornerstone of the next industrial revolution. By providing a unique representation of complex systems and processes and connecting real life with virtual worlds, we provide our clients trusted environments to learn, innovate & operate, capitalizing on their knowledge & know-how.

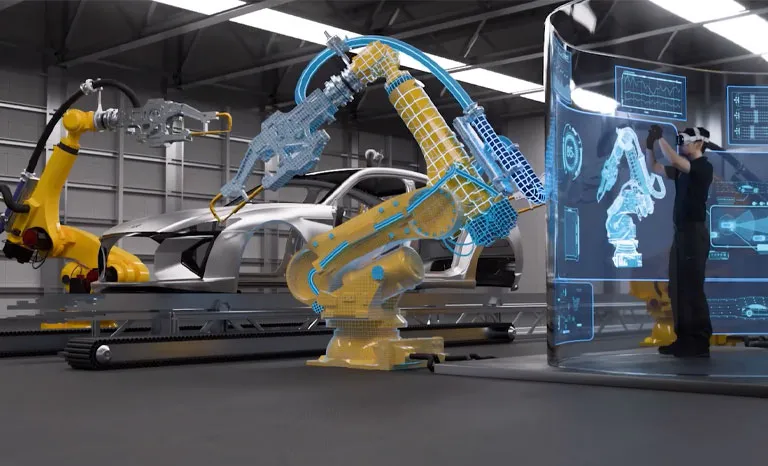

Transforming the automotive industry with AI-powered virtual twins

AI-driven design in manufacturing industries enhances creativity and precision, while virtual simulation optimizes performance before production.

By leveraging artificial intelligence and virtual twin technologies, engineers can design safer, smarter, and more sustainable vehicles at unprecedented speed, driving a worldwide transformation of the automotive industry.

Supporting every phase of the production lifecycle — from ideation to manufacturing — virtual twins empower creators and operators to simulate, test and optimize before any product or process is built. This fosters innovation along with sustainable decision-making, helping manufacturers reduce environmental impact and carbon emissions at every stage of the process.

By reimagining how goods are designed and produced, virtual twin experiences shift focus from one-size-fits-all products to personalized, evolving solutions and from rigid, centralized methods to flexible, adaptive systems. They help anticipate future needs by balancing progress with environmental responsibility.

Dassault Systèmes goal — indeed, our obsession — is to deliver virtual twin experiences that enable the creation of sustainable products and services, harmonizing product, nature and life without compromising future generations.

Our virtual twin experiences are catalysts for transformation. By combining modeling, simulation, data-science & AI-generated content, they enable us to drive unprecedented advancements in design, engineering, manufacturing and beyond. With virtual twins, we are redefining what's possible, setting new standards for industry and shaping the future of technology.

From Virtual Twins to Generative Experiences: How AI Is Revolutionizing Manufacturing

Dassault Systèmes empowers manufacturers with AI-driven Virtual Twins and Generative AI to optimize design, production, and performance, accelerating innovation and sustainable industrial transformation.

How Do Virtual Twins Go Beyond Digital Twins in Manufacturing?

Virtual twins extend digital twins by merging virtual and real-world data to create dynamic, experience-driven models. They enable real-time simulations and optimizations, transforming manufacturing from traditional production to experience creation.

By integrating simulations and digital data, virtual twins drive innovation, enhance efficiency and play a key role in reducing carbon emissions, shaping sustainable manufacturing ecosystems to positively impact the future.

The World Needs Manufacturers

Manufacturing is at a crossroads, facing pressures from geopolitical tensions, rising customer demands and environmental challenges. At the same time, advancements like smart factories and new technologies such as AI offer opportunities to rethink operations.

In our Manufacturing Industries Trends Guide, we explore key trends, their impact on business transformation and steps to take now to prepare for the future.

Experience the Future of Vehicle Innovation

Discover how the 3DEXPERIENCE platform accelerates sustainable vehicle development—from concept design to engineering and manufacturing—through immersive virtual twin experiences.

Bringing Virtual Twins to Apple Vision Pro

See how virtual twins come to life with Apple Vision Pro. With 3DLive, teams can visualize and interact with lifelike models in their physical environment—unlocking immersive collaboration, real-time insights and scientifically accurate simulations.

Revolutionizing Manufacturing Industries with Virtual Twins

Explore how virtual twins are transforming manufacturing with precision and innovation to improve product outcomes.

How Virtual Twins Address Challenges in Products, Production Systems and Organizations

Discover how virtual twin technology enhances products, optimizes production systems and transforms organizations to drive performance and resilience.

Virtual twin of a product

Simulate, analyze and optimize the behavior and lifecycle of a physical product through a scientific digital replica that evolves with real-world data—enabling smarter decisions and improved performance.

Virtual twin of a production system

Model, simulate and optimize end-to-end production systems as dynamic, data-driven ecosystems. Integrate processes, supply chains, resources and operations to test scenarios, improve performance and support agile, sustainable decision-making.

Virtual twin of an organization

Visualize, analyze and steer your organization as a dynamic system of systems. Connect value networks, simulate future scenarios and uncover strategic opportunities to boost resilience and business performance.

Real-World Applications of Virtual Twins in Manufacturing Industries

Virtual twins are revolutionizing manufacturing by adding value across all lifecycle stages, from planning facilities and processes to production. Serving a wide range of industries, virtual twins allow products and processes to start in the virtual realm, and be subject to simulations to optimize designs and workflows.

Once production is live, real-time data is fed back to the virtual twin, driving continuous improvements in efficiency, quality and adaptability. Virtual twins enable manufacturers to enhance operations, reduce costs and meet industry-specific regulations and challenges with speed.

Let’s explore how virtual twins are being applied in real-world scenarios by Dassault Systèmes customers, driving innovation and solving complex challenges across various manufacturing sectors.

L'OCCITANE en Provence, Laboratoires M&L

L'Occitane en Provence leverages virtual twin technology to enhance manufacturing efficiency and ensure safety in their factories.

Virtual Twin as a Service (VTaaS) empowers the company to quickly simulate real-world operations, optimize processes and create safer, more sustainable production environments.

This approach enables continuous improvements, helping them meet high standards for quality and operational excellence.

Virtual Twins Across Manufacturing Industries' Value Chain

Bringing end-to-end visibility, intelligence and optimization to every stage of the manufacturing lifecycle.

Ready to Dive Deeper and Discover Our Brands Specializing in Manufacturing Industries?

Dassault Systèmes portfolio includes powerful 3D modeling, simulation and information intelligence applications that enable manufacturing industries to create virtual twins for optimized products and operations.

Powered by the 3DEXPERIENCE platform, our brand solutions seamlessly connect data and processes—driving sustainable innovation across the entire product lifecycle.

Our approach is rooted in end-product thinking. We build on deep expertise to support every phase: from creation and operations to continuous improvement. This generates virtual twins that evolve with the product or process, enhancing performance and sustainability over time.

Virtual twins accelerate a wide variety of products, including vehicles, satellites, aircraft, electronic devices, semiconductors and autonomous mobile robots.

Take a closer look at how we make it happen by exploring our brand portfolio.

Curious About Virtual Twins? Find Answers in Our FAQ.

You Might Want to Explore...

About our company

We’re in the business of innovation. Through our unique solutions, we bring virtual twin experiences to everyone – including you!

Virtual Twin as a Service

VTaaS provides the expertise, equipment, and maintenance for virtual twins, delivering the value you need without the complexity.

Online store

Kick-start your design journey in a cloud-based collaborative space to foster innovation from day one.

Contact sales

Have a Dassault Systèmes expert contact you to answer your questions and discuss any of your needs.