Beauty & Personal Care

Build your beauty & personal care products portfolio in the CPG & Retail Industry around more natural and high performing products that will keep consumers coming back for more.

Transforming the Beauty Industry With Digital Innovation

The beauty industry, now valued at $450 billion¹, has always thrived on reinvention. Today, consumers expect more — personalized cosmetics, cruelty-free products and sustainable packaging. Online channels are booming too, projected to make up nearly one-third of global beauty sales by 2030, up from 26% in 2024². With stricter regulations and global supply pressures reshaping the landscape, innovation has become non-negotiable.

But tomorrow’s beauty breakthroughs won’t come from another new scent or shade. They’ll come from a digital makeover behind the scenes, where digital beauty labs optimize formulations, smart factories bring creativity to scale and AR try-ons let consumers try, feel and connect before they buy. For market leaders, the message is clear: Now is the time to make digital innovation your most powerful ingredient — and define what beauty means next.

Solving Key Challenges in the Beauty Industry

Competition is intensifying, margins are tightening and consumers are more discerning than ever. To stay ahead in today’s beauty and personal care market, leaders must rethink what drives growth and design business models and products that deliver real performance.

- Formulation complexity

- Regulatory requirements

- Accelerating time-to-market

- Sustainability goals

- Regional market trends

Managing product formulation complexity

Consumers are becoming increasingly health-conscious. They read every label and prefer products with natural, active ingredients. This demand adds new layers of complexity to beauty product formulation. For beauty manufacturers, solving this challenge means digitalizing and streamlining formulation processes to ensure safe, high-performing products.

By reimagining the lab as a connected digital environment, research and development (R&D) teams can design, test and perfect products virtually before they ever reach the bench. With ingredient-level precision and real-time collaboration powered by advanced beauty manufacturing software, manufacturers can balance performance and cost while keeping compliance in check. The result? Faster innovation cycles, safer products and formulations that deliver exactly what consumers want.

Meeting clean beauty and regulatory requirements

Transparency now defines the future of beauty. Yet, as clean and inclusive standards rise, regulations are changing faster than many companies can adapt. From state-level policies in the US to new legislation across the UK and EU, the pace shows no sign of slowing. The challenge? Regulatory compliance is still often a highly manual process: Collecting status reviews, discovering changes late in the process and making last-minute decisions on the right materials to be used.

To stay ahead, leaders in the beauty industry must centralize global regulatory intelligence on a single digital platform — enabling real-time monitoring of global standards, proactive decision-making and complete confidence that every product reaching consumers’ homes is safe, effective and compliant.

Accelerating time-to-market with digital R&D

Lengthy, manual R&D cycles often hold back beauty innovation. Teams work in silos, data gets lost between systems and testing takes too long to validate new formulations — delaying great ideas from reaching the market. Solving this challenge starts with breaking down these silos through beauty R&D digitalization.

Digital R&D transforms end-to-end beauty product lifecycle management. By connecting data, teams and processes on a unified digital platform, manufacturers can accelerate design and innovation cycles. With every ingredient, experiment and approval traceable in one place, beauty manufacturers can operate with the precision of big pharma, moving from concept to consumer in record time while reducing risk, cost and complexity.

Achieving sustainability goals in packaging and manufacturing

As sustainability expectations rise, beauty manufacturers face pressure to design packaging that’s refillable, recyclable and carbon-conscious. Yet many still struggle to connect design, sourcing and production in a way that truly drives measurable change.

The answer to sustainable beauty packaging lies in going digital. A connected platform brings full visibility across materials, suppliers and processes — helping teams track environmental impact and make more responsible choices at every stage of product development. With AI-powered formulation and lifecycle management, companies can accelerate more green products and packaging that meet sustainability goals and consumer expectations alike.

Adapting to regional market demands and trends

Winning new market share depends on how fast companies can translate global standards into local success. Yet even world-class beauty manufacturers face complexity in today’s inclusive beauty industry — where diversity, compliance and speed must coexist.

The key to overcoming this? Managing data effectively. Many beauty leaders are turning to product and packaging specifications management to drive speed, efficiency and savings. Imagine sourcing raw material equivalents that meet local regulations while staying cost-effective, or updating packaging artwork instantly for regional launches. With a digital solution built on a single source of truth, global teams can access all ingredient, material, packaging and costing information in one place. The payoff? Faster localization, consistent quality and products that resonate in every market.

Unlock Beauty Innovations with the 3DEXPERIENCE® Platform

End-to-end digital continuity from R&D to production

Drive cross-functional collaboration through a single platform.

Simulate, validate and launch new products faster

Use digital twins and virtual labs to test, iterate and scale innovations.

Structure specifications to ensure global compliance

Maintain consistency and traceability across markets and partners.

Key Benefits of Our Digital Solutions for the Beauty Industry

Faster time to market

Accelerate product development with integrated digital tools and connected data.

Improved regulatory compliance

Track ingredient regulations in real time and ensure global labeling accuracy.

Enhanced product quality and brand trust

Ensure safe, effective and traceable beauty innovations.

Sustainability by design

Optimize design for refillable, recyclable or carbon-neutral packaging.

Personalized product development

Develop custom formulations and smart beauty experiences tailored to customers.

Unified product data management

Give every team instant access to accurate, up-to-date product and packaging data.

The Future of Beauty Is Digital, Personal and Uniquely Human

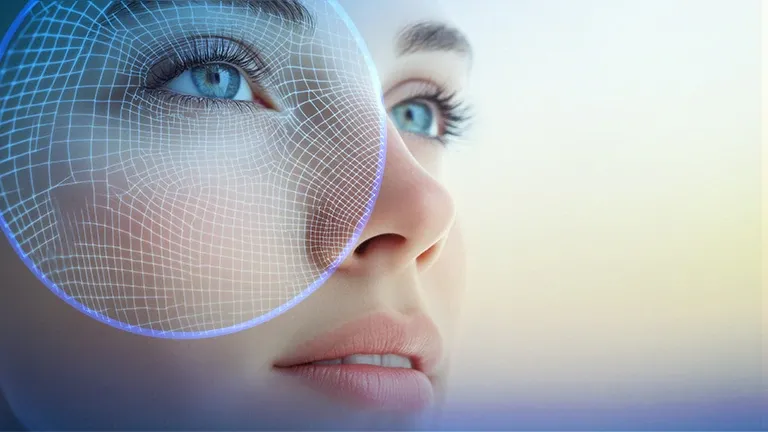

As the pace of change accelerates, innovation in beauty is no longer limited to the lab; it’s happening everywhere consumers connect, test and express themselves. Smart beauty devices now analyze skin conditions in real time, while AI-powered diagnostics personalize routines like never before. Augmented reality has made discovery personal and playful, turning virtual try-ons into data-driven insights that inspire the next breakthrough formula.

At the same time, the inclusive beauty movement is reshaping what success looks like — urging brands to reflect diversity, individuality and accessibility in every product they launch. From adaptive shade ranges to region-specific formulations, forward-thinking beauty leaders are proving that technology and inclusivity can go hand in hand. When processes are digitalized and data leads the way, personalization at scale becomes the new standard in the beauty industry.

Real Results from the World’s Most Iconic Beauty Brands

From sustainable, paperless operations to real-time production visibility, discover how top beauty manufacturers are redefining the industry with our digital solutions. Your business could be the next success story.

L’Occitane en Provence

Built a “safe factory” integrating compliance and traceability to cut ramp-up time and drive a zero-accident culture through virtual twins.

Grupo Boticário

Connected operations and accelerated innovation across teams, driving traceable and paperless manufacturing.

Ultimately, we’ve found value, efficiency and opportunities for a cleaner, greener future. The partnership we have with Dassault Systèmes gives us reliable, robust results. It will help us to write a new chapter in the history of Laboratoires M&L for the L’OCCITANE Group.

Marketing Programs To Transform Your Beauty Business

Discover how the 3DEXPERIENCE platform and virtual twins drive measurable impact across the beauty value chain. Through these programs, see how digital transformation enables faster innovation, stronger sustainability and more meaningful consumer connections.

Beauty Manufacturing Excellence

Differentiate your value proposition while optimizing production efficiency and reducing material costs.

Clean Beauty Transformation with Regulatory Readiness

Accelerate growth and meet consumer demand for healthier products while driving sustainability initiatives and regulatory compliance for maximum efficiency.

Personalization at Scale with Virtual Beauty Labs

Build your beauty and personal care products portfolio in the CPG&R industry around more natural and high-performing products that will keep consumers coming back for more.