Artificial Intelligence in Manufacturing & Supply Chain

Transform your operations with Artificial Intelligence in manufacturing and supply chain to enhance efficiency, predict demand, and streamline logistics.

What is AI in Manufacturing and Supply Chain?

Artificial Intelligence (AI) in manufacturing and supply chains refers to the use of AI technologies to optimize operations, improve efficiency, support workforce development, and enhance decision-making.

By leveraging AI-driven technologies like predictive maintenance, demand forecasting, quality control, supply optimization, and supply chain automation, organizations can minimize downtime, improve responsiveness, and stay competitive. At the same time, AI supports frontline workers by providing real-time guidance, accelerating onboarding, and helping close skill gaps, enabling a more adaptable and empowered workforce in the face of operational complexity and labor shortages.

Generative insights + Operational Reality

Industrial AI turns production and supply chain data into real-time intelligence in 3D UNIV+RSES; driving efficiency, agility, and resilience across manufacturing and supply chain operations.

Key Features of AI in Manufacturing and Supply Chain

Enhance Personalization

Artificial Intelligence helps companies tailor products or services to individual customer preferences, enhancing customer engagement and driving repeat business.

Scale and Adapt

Artificial Intelligence systems are highly scalable, allowing businesses to adapt quickly to market changes, new technologies, and increased demand, ensuring long-term competitiveness.

Make Data-Driven Decisions

Artificial Intelligence processes vast amounts of data to provide actionable insights, enabling manufacturers to make data-driven decisions that positively impact their bottom line.

Task Automation and Guidance

AI improves industrial operations by automating routine tasks, optimizing processes, and reducing downtime. It also supports workers with real-time guidance, faster onboarding, and skill development, leading to greater efficiency and better product quality.

AI in Manufacturing & Supply Chain Drives Sustainability

Artificial Intelligence is revolutionizing sustainable practices in manufacturing and supply chains. By uncovering inefficiencies, predicting resource needs, optimizing energy consumption, and reducing excess inventory, AI helps businesses minimize their environmental impact while boosting operational efficiency.

AI also supports circular economy initiatives by enabling smarter resource use, predicting product lifecycles, optimizing recycling processes, and facilitating closed-loop supply chains through data-driven insights.

Transforming Industries with Artificial Intelligence in Manufacturing and Supply Chains

- AI in Manufacturing

- AI in Supply Chain Planning and Scheduling

AI Applications in Manufacturing

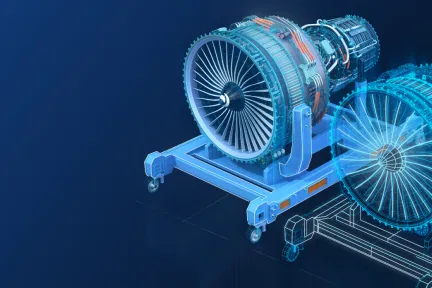

AI is revolutionizing manufacturing by enabling predictive maintenance through machine learning (ML). By analyzing historical and real-time equipment data, AI identifies patterns and predicts potential failures that could lead to cost reductions of up to 30%. Generative AI is also being used to accelerate workforce operations on the shopfloor. The numerous use-cases enhance efficiency and improve decision-making through various applications:

- Predictive Maintenance: Detects equipment issues early to prevent unplanned downtime and lower maintenance costs.

- Operational Efficiency: Automates repetitive tasks, recommends more efficient operations, and improves lead times.

- Quality Control: Uses predictive analytics to identify defects early, ensuring consistent product quality.

- Energy and Cost Savings: Reduces waste, minimizes errors, and optimizes resource utilization.

AI in Supply Chain Planning & Scheduling

In supply chain management, Artificial Intelligence processes vast data sets to optimize resource allocation, enhance demand forecasting, and streamline scheduling. By integrating AI technologies, companies can make agile, data-driven decisions, improve service levels, and efficiently manage inventory.

Optimizing Industrial Operations in Many Areas with AI

Incorporating Artificial Intelligence into industrial operations brings significant benefits:

Enhancing Manufacturing with Generative AI and Augmented Reality

Augmented Reality (AR) in manufacturing overlays critical information like blueprints and real-time data to improve production, assembly, and quality processes. When combined with Artificial Intelligence (AI), AR systems can detect anomalies, alert operators, and adjust parameters in real time for optimal performance. AI-powered AR also uses machine learning to recognize objects and movements with precision, enhancing decision-making and efficiency in complex manufacturing environments. Generative experiences leverage extensive manufacturing data, such as complex machining, to assist workers in determining optimal processes for manufacturing operations based upon historical performance and requirements.

Start Your Journey

The world of artificial intelligence in manufacturing & supply chain is changing. Discover how to stay a step ahead with DELMIA.

FAQs about AI in Manufacturing and Supply Chain

Also Discover

Learn What DELMIA Can Do for You

Speak with a DELMIA expert to learn how our solutions enable seamless collaboration and sustainable innovation at organizations of every size.

Get Started

Courses and classes are available for students, academia, professionals and companies. Find the right DELMIA training for you.

Get Help

Find information on software & hardware certification, software downloads, user documentation, support contact and services offering