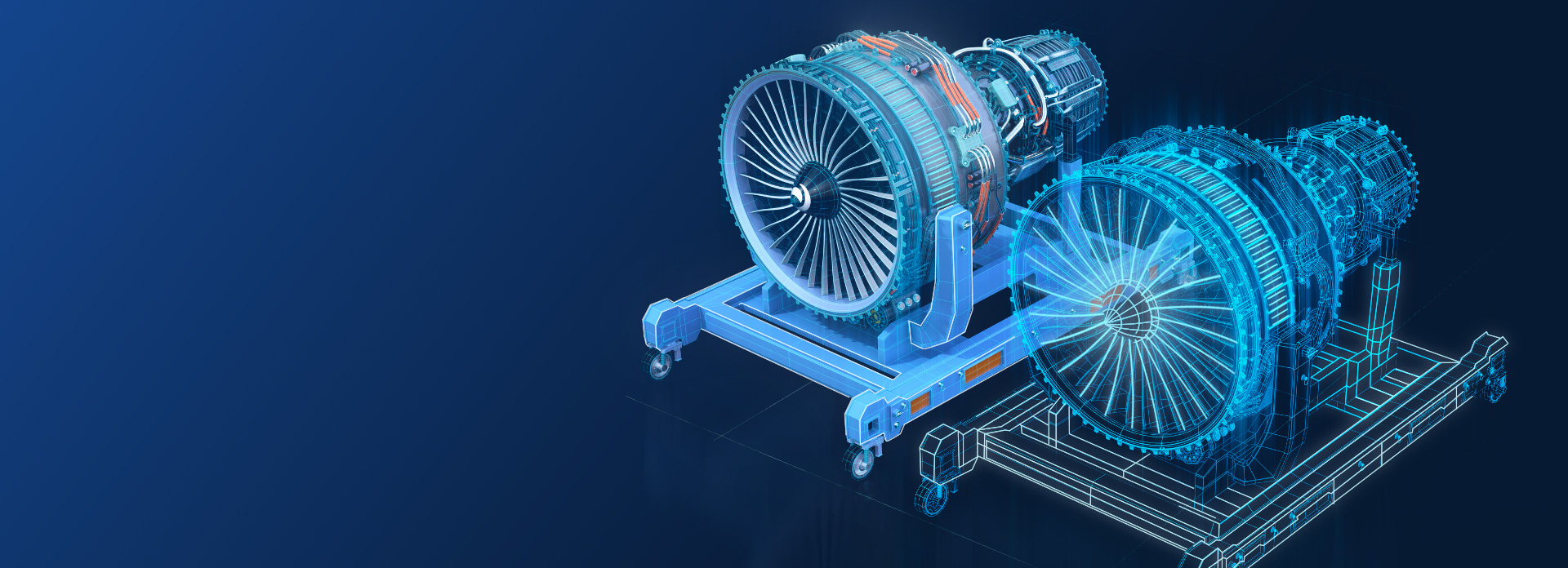

Virtual Twin for Manufacturing

Visualize, simulate and optimize your manufacturing with a real-time virtual twin that goes beyond the digital twin experience.

Manufacture Right the First Time

DELMIA’s Virtual Twin for Manufacturing goes beyond digital twins. It enables you to model, simulate and visualize every aspect of manufacturing - from product, processes and plant layout to logistics and supply chain execution - driving sustainability, innovation, safety, and profitability. It’s a dynamic, data-driven representation of reality, providing bidirectional feedback for a tightly-connected design-to-manufacturing loop.

Expand digital models into an actionable virtual twin. This allows you to optimize processes between engineering and production, including assembly, testing, maintenance and delivery, augmented reality and interactive 3D technology.

Virtual Twin for Manufacturing Key Features

3D Model-Based Capability

Represents assets, business processes, infrastructure, and metrics

Unlimited Simulation

Experiment virtually and determine the best configuration in the real world

Closed-Loop Connection

Allows real-time updates to refine and optimize processes for a long-term strategy continuously

Advanced Manufacturing Techniques

Capture contextualized data

Augmented Reality

Improve process execution, quality, and workforce productivity & satisfaction

Virtual Design and Simulation

Make processes and facilities more sustainable

Transforming the Future with DELMIA Virtual Twin

- Manufacturing Operations Management

- Supply Chain

- Virtual Twin Technology

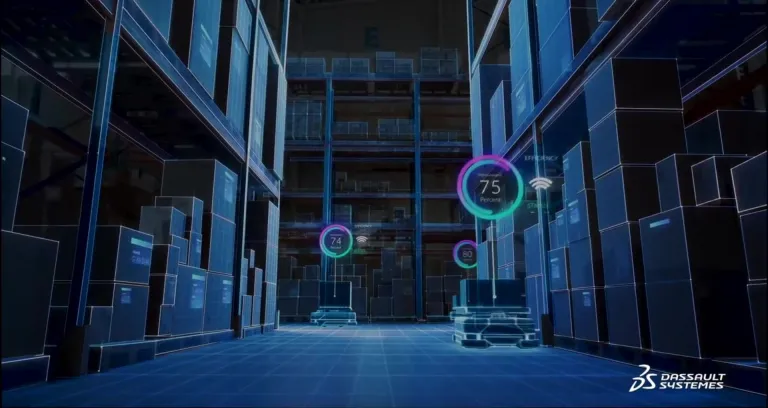

Manufacturing Operations Management

DELMIA Manufacturing Operations Management (MOM) software provides key capabilities for manufacturing sustainability. IIoT (Industrial Internet of Things) connectivity enables the monitoring of production processes and resources in real time. This provides visibility to inefficiency and enables intervention through machine maintenance and process improvement. This, in turn, leads to higher quality and reduced scrap, which reduces waste in both lost material and repeat production.

Increased efficiency reduces CO2 footprint by maximizing products produced per time period. Connection to environmental systems, like water and energy consumption, facilitates the identification of hotspots, enabling targeted reduction measures.

Supply Chain

Ongoing disruption requires a fundamental shift in supply chain strategy. Increasingly, companies are realizing that to orchestrate supply chain excellence they need to collaborate with other disciplines. To obtain true levels of resiliency, DELMIA’s supply chain planning and optimization software focus on visibility, integration and orchestration across the entire product lifecycle, from design to manufacturing.

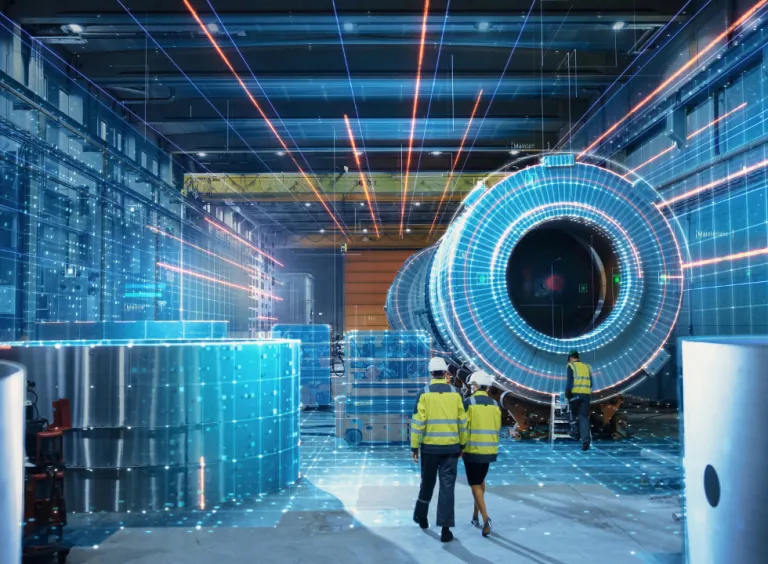

Virtual Twin Technology

At DELMIA, we believe the virtual world improves manufacturing’s reality. Our solutions go beyond digital twin technology to foster sustainability, innovation, safety, and profitability in delivering products and services.

Through a virtual twin experience, you can model, simulate, and effectively visualize feasible real-world implementations—spanning production, plant layout, operations, and logistics across the global supply chain.

DELMIA Virtual Twin for Manufacturing Experience

DELMIA Virtual Twin for Manufacturing goes beyond the static representation of digital twins. It is a dynamic virtual model of real-world products, facilities, assets, and processes powered by real-world data, allowing manufacturers to collaborate, model, optimize and perform efficiently. Simulating outcomes of multiple scenarios in the virtual model helps manufacturers form the best plans in line with business and sustainability goals.

The Virtual Twin, enhanced by generative AI, provides real-time, data-driven insights and decision support, enabling manufacturers to optimize operations, simulate scenarios, and uncover new opportunities. This integration empowers businesses to reduce risks, enhance sustainability, and upskill their workforce through innovative, AI-driven experiences.

Key Benefits of DELMIA Virtual Twin for Manufacturing

DELMIA Virtual Twin as a Service: Your Shortcut to Value

Virtual Twin as a Service is an online solution that we build, deploy and manage for you, all in a single cloud subscription. Leveraging over 40 years of knowledge, know-how and industry expertise, we provide the insights you need — risk-free, on time and within budget. This allows you to focus on your core business where your expertise truly lies.

The benefit of using virtual twin technology to improve your manufacturing business is obvious. However, do you have the resources, expertise and time to do it properly? Our team of experts takes care of building and managing virtual twins for you, so there’s no need for expensive infrastructure or hiring specialized teams. It’s a low-risk, efficient solution, giving you expert insights and the flexibility to adapt as your business grows. With 40+ years of expertise behind it, VTaaS helps you innovate faster and focus on growing your core business goals.

Start Your Journey

The world of manufacturing & operations is changing. Discover how to stay a step ahead with DELMIA Virtual Twin for Manufacturing.

FAQs about Virtual Twin in Manufacturing

Learn What DELMIA Can Do for You

Speak with a DELMIA expert to learn how our solutions enable seamless collaboration and sustainable innovation at organizations of every size.

Get Started

Courses and classes are available for students, academia, professionals and companies. Find the right DELMIA training for you.

Get Help

Find information on software & hardware certification, software downloads, user documentation, support contact and services offering